Winter is the time when outdoor gardening stops and gardeners move indoors to get their power equipment ready for spring.

I took care of most of my equipment this winter, but not all. As the weeks went by, some things got pushed to the back of the storage shed. It’s like they went into hibernation and are just now waking up to see the light of day.

This week I dragged all my power tools outside to make sure they would start. All ran fine except one. It is powered by a two-cycle engine — sometimes called a two-stroke engine. You know, one of those that you have to mix oil into the gasoline. String trimmers, chainsaws, leaf blowers are some of the most common tools that use this type of engine.

A two-cycle outdoor tool that has lost its power or won’t start or is hard to start, probably has carbon build up on the exhaust port. And that’s exactly what happened to mine.

Two-cycle engines require unobstructed air flow to run properly. After many hours of use, carbon deposits inevitably build up on the exhaust portion of the engine –especially if it is run at slow speeds — making it hard or impossible to start.

Fortunately, cleaning those carbon deposits are a doable project for someone with a little mechanical know-how. It’s a good project to try if you want to progress beyond blade sharpening or oil changing.

Here’s one way to do it.

For safety sake it’s always a good idea to get into the habit of disconnecting the spark plug wire whenever working on gasoline powered engines.

Remove the heat shield from the muffler.

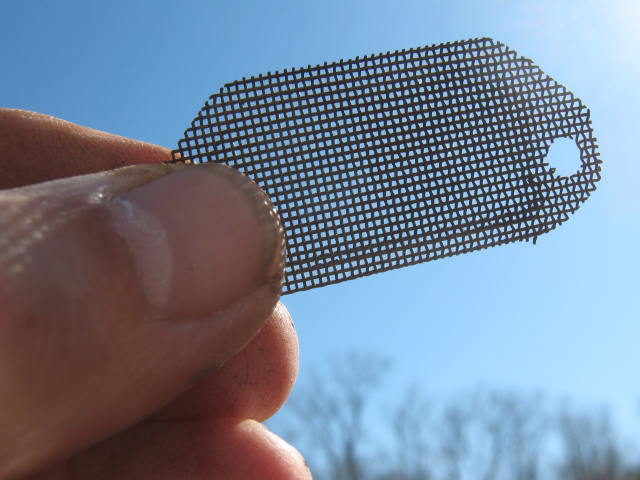

Then un-bolt the muffler from the engine which will expose the exhaust port. You’ll be able to see the carbon caked onto the exhaust opening.

Slowly pull on the starter rope to bring the piston up to cover the port opening. That will keep loose particles from falling into the cylinder. Stray particles inside the cylinder will cause scoring of the piston and cylinder walls, then you’ll have a bigger problem to deal with than just carbon deposits.

Use a small piece of hardwood sharpened to a point– or a screwdriver if the carbon is really tough — to carefully scrape off the carbon. Don’t dig into the underlying metal and be extra careful not to scratch the piston!

Once you have the carbon loose, vacuum it up with your shop vac.

Check the muffler and other parts for carbon build up too before you reassemble everything.

The engine should start easily and will have more power. This is the first thing a repair shop will do when they get a two-stroke engine . So it makes sense to try this first before taking it into the repair shop. You’ll save money and be able to use your machine right away instead of waiting weeks for it to get repaired.

Bob